Excavator machines are vital machines in the construction and mining industries, renowned for their flexibility and power. Grasping the multiple components of an excavator is crucial for individuals involved in operating, upkeeping, or buying this heavy equipment. By familiarizing yourself with the main excavator parts, you can improve your familiarity and make informed choices regarding their utilization and maintenance.

From the strong engine that powers the equipment to the hydraulic system that manage its movements, every element plays a critical role in the complete functionality of an excavation machine. In this overview, we will explore the essential elements of an excavation equipment, allowing you to grasp how they interact to carry out a multitude of jobs, from excavating ditches to hoisting large loads. Whether you are a experienced user or a newcomer to the industry, comprehending these elements will increase your respect of this impressive piece of equipment.

Types of Excavator Parts

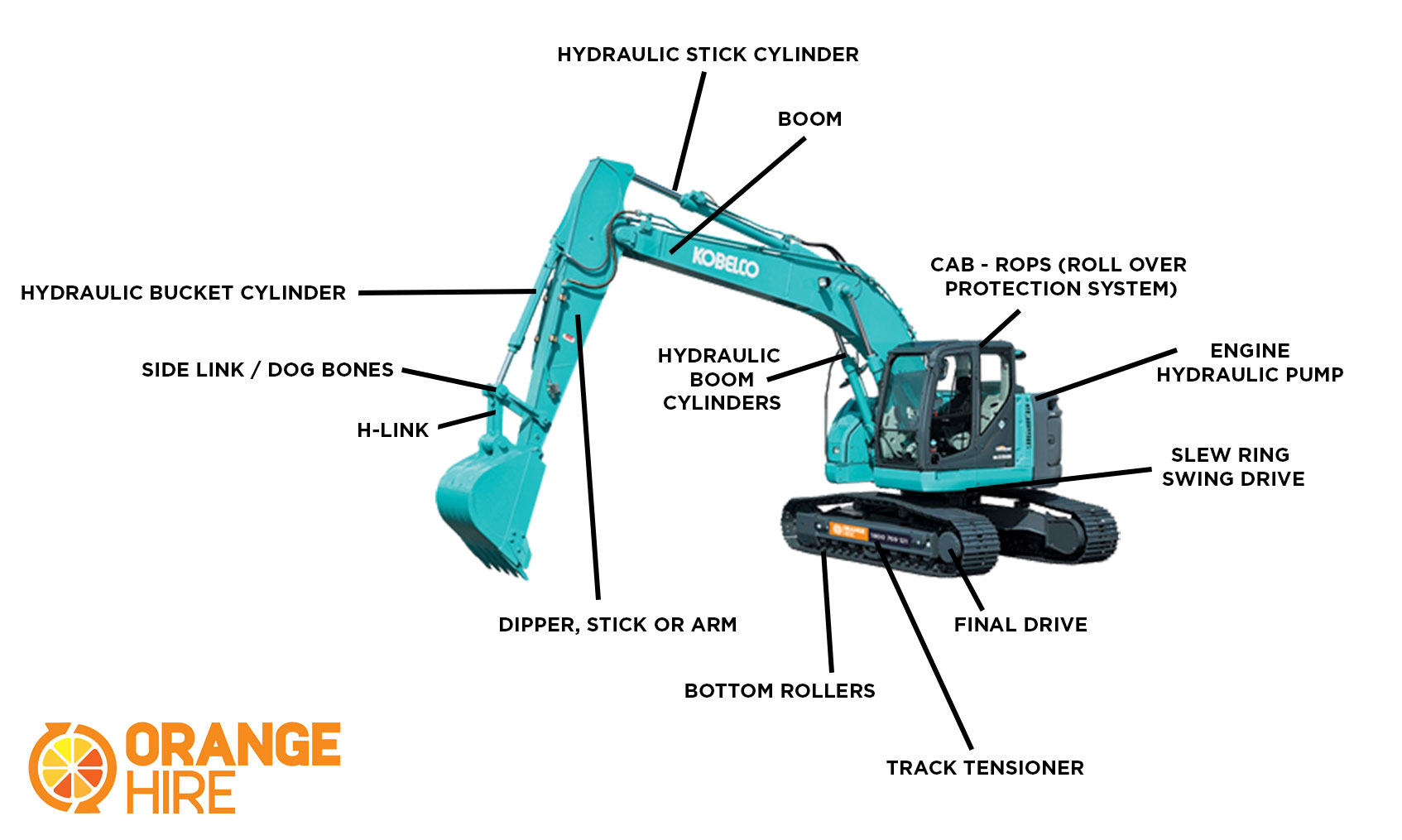

Excavator machines consist of several important parts that work together to carry out multiple tasks on building sites. The main components comprise the undercarriage, the cab, and the implement systems. The base is important for mobility and balance, featuring tracks or wheels designed for different terrains. The upper structure is the upper structure that houses the driver’s cabin and motor, providing the essential power and oversight for the excavator's functionality.

Another important group of elements constitutes the arm, stick, and digging tool. The arm is a prolonged component that protrudes from the upper structure, while the stick acts as a link between the boom and the tool. Collectively, they provide the required reach and digging depth. The digging tool , connected with the stick, is the instrument that performs the primary digging or lifting tasks. Different types in digging tools can tailor the excavator for targeted jobs, from ordinary digging to narrower tasks.

Finally, the excavator’s hydraulic system plays an crucial role in its performance. This system manages the action of the boom, rod, and bucket, allowing for accurate and forceful actions. The hydraulic components include gear pumps, cylinders, and lines that work under high pressure to ensure fluid and agile operation. Grasping these basic parts is important for those who are using or maintaining an excavator, as they directly impact performance and productivity.

Functionality of Key Components

The main body of an excavator, often referred to as the house, is where the operator sits and operates the machine. This component houses the engine, hydraulic pumps, and electronic system, which are crucial for the excavator’s functioning. The house spins on the base, allowing the machine to navigate easily around a work site while ensuring access to the dig site. It is engineered to provide steadiness and support the weight of the parts above.

The arm and stick are key components that work together to reach and excavate. cat parts is the big arm that extends forward and upward, while the stick, or dipper, is attached to the end of the boom and enables for extra reach and precision in digging. These components are connected via hydraulic systems, which provide the necessary power and versatility for different tasks. They can be raised, dropped, and stretched to different angles, making them versatile for multiple excavation jobs.

The bucket is the most recognizable part of an excavator and is primarily utilized for excavating and moving earth or resources. Different types of buckets can be attached, depending on the job, whether it's a standard digging bucket, a trenching bucket, or even specialized buckets for managing specific substances. The hydraulic system drives the movements of the bucket, allowing it to gather, raise, and dump heavy loads efficiently, significantly enhancing the excavator's efficiency on job sites.

Maintenance Tips for Excavation Parts

Regular maintenance is vital to maintain the longevity and efficiency of your excavator parts. Begin by performing routine inspections of major components such as the treads, dipper, and hydraulics. Look for signs of wear or issues, as early detection can avert costly repairs. Maintaining the excavator clean and clear of obstructions can also help prevent unnecessary strain on the parts.

Oil changes are important as they keep the engine and hydraulic systems operating effectively. Follow the manufacturer's recommendations for oil change intervals and always use the recommended oil type. Additionally, monitor the levels of hydraulic fluid and coolant consistently to prevent overheating and maintain optimal performance. Proper lubrication of pivot points and connections will reduce friction and extend the life of these moving parts.

Educating operators on proper usage techniques can greatly reduce damage on excavator parts. Ensure that they comprehend the limits of the machine and avoid actions that could lead to issues, such as overfilling the bucket or driving on uneven ground. Creating a scheduled maintenance program and keeping records of service history will also help keep track of repairs and replacements, ensuring that the excavator remains in top condition.